CASTING

We specialize in gravity and low-pressure casting, carried out by pouring molten brass into molds —known as permanent molds — which are designed and manufactured according to customer specifications and reused across multiple production cycles.

HOT FORGING

In hot forging of brass, aluminum, and stainless steel, the metal bar is first heated and then shaped under the force of a press, transforming it into the desired form with precision and strength.

MATERIALS AND PROCESSES

Brass, stainless steel, aluminum, and plastic: our range is extensive, and our ability to work with different metals and alloys allows us to achieve excellent results. We can recommend the most suitable material for every requirement.

Main brass alloys:

- CW617N: Reliable, versatile, ideal for complex machining.

- CW510L / CW511L: Low-lead brass compliant with UBA and DWD, safe for drinking water.

- CW724R (Ecobrass): Completely lead-free, with high resistance to dezincification.

CNC LATHES

13 modern CNC lathes, ideal for complex and high-precision machining.

Automatic bar capacity from Ø6 mm to Ø95 mm, with machining up to Ø300 mm.

Perfect for a wide range of materials and geometries.

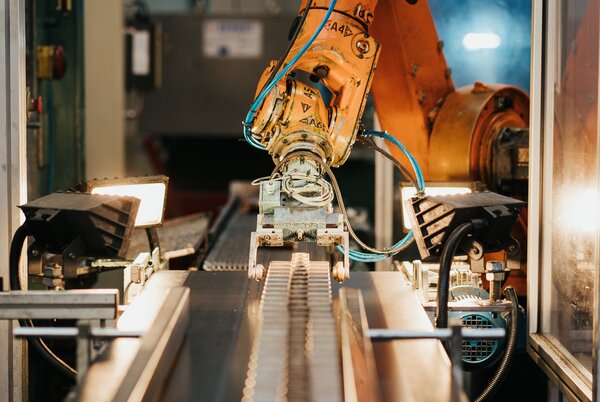

5-AXIS MACHINING WORK-STATIONS

6 state of the art 5-axis work-stations, ideal for machining semifinished products from forging or casting, ensuring maximum precision and flexibility.

Equipped with automated loading and unloading, they enable efficient management of production cycles.

TRANSFER machines

4 transfer machines dedicated to processing large batches from forging or casting.

Simultaneous operations across multiple stations drastically reduce cycle times and costs.

DIMENSIONAL INSPECTION

Through our dedicated metrology laboratory, we ensure precise dimensional conformity between design and finished product at every stage of the production process, using advanced measurement and inspection systems to guarantee accuracy and reliability.

ASSEMBLY AND TESTING

An in-house assembly line completes the production process, allowing all required inspections and functional tests to be performed on each individual component, ensuring quality and performance before packaging and shipment.

ADDITIONAL SERVICES

In addition to continuous quality control, GIAMI offers cleaning services, galvanic treatments, painting, and PVD coatings. We also provide customized logistics solutions to ensure continuity in both production and service.